Garrard 301 Restaurierung

Restaurierung eines Garrard 301

Ich habe meinen Garrard 301 auf Ebay in ziemlich schlechtem Zustand gekauft. Allerdings war das Risiko angesichts des geringen Preises vertretbar.

Falls Sie den Garrard 301 noch nicht kennen, eine Googlesuche oder aber das Garrard Forum auf ‚Vinylengines‘ (Englisch) bringen weitere Informationen.

Eine kurze Zusmmenfassung des Zustands:

- Der Einschalt- und Geschwindigkeitshebel waren abgebrochen,

- Der Teller war oxidiert,

- Das Hauptlager lief ruhig

- Der Motor war verharzt

- Das Reibrad war in gutem Zustand.

Ich habe den Spieler komplett demontiert, um alle Metallteile glasperlen zu lassen (wesentlich feiner als Sandstrahlen). So konnte die Oxidschicht sauber entfernt werden. Nicht vergessen die Tellerachse und die Innenseite mit Pappe und Klebeband zu schützen.

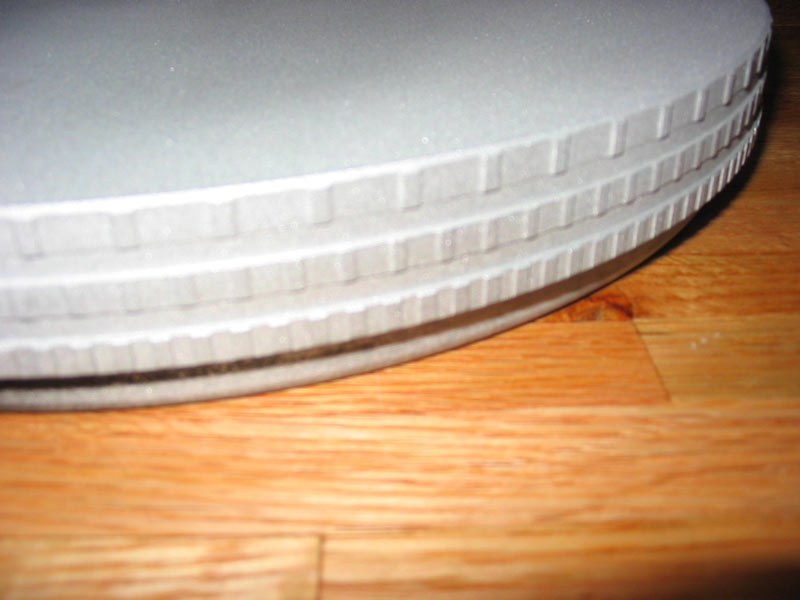

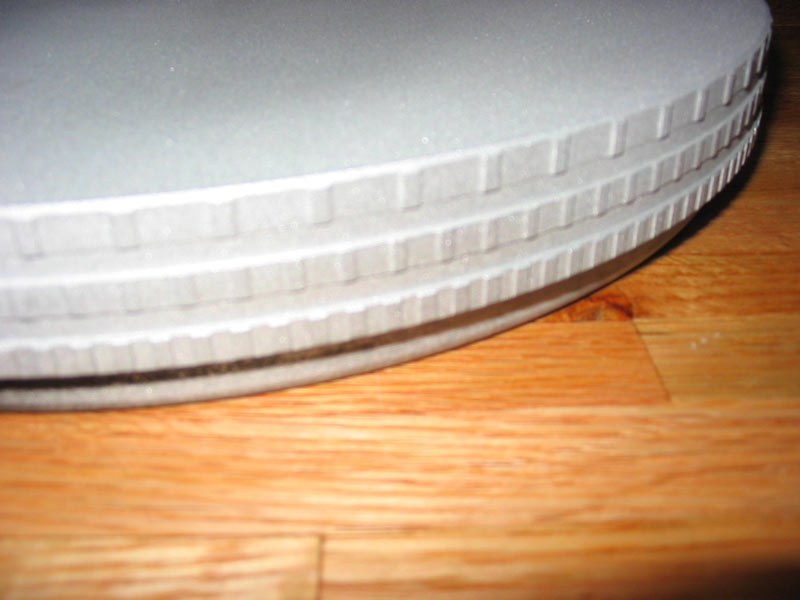

Der ‚leidende‘ Teller im Detail.

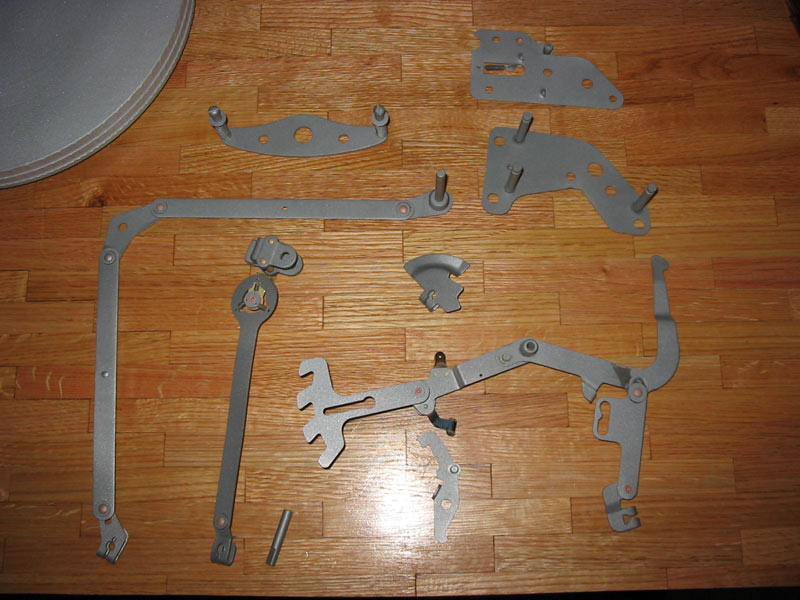

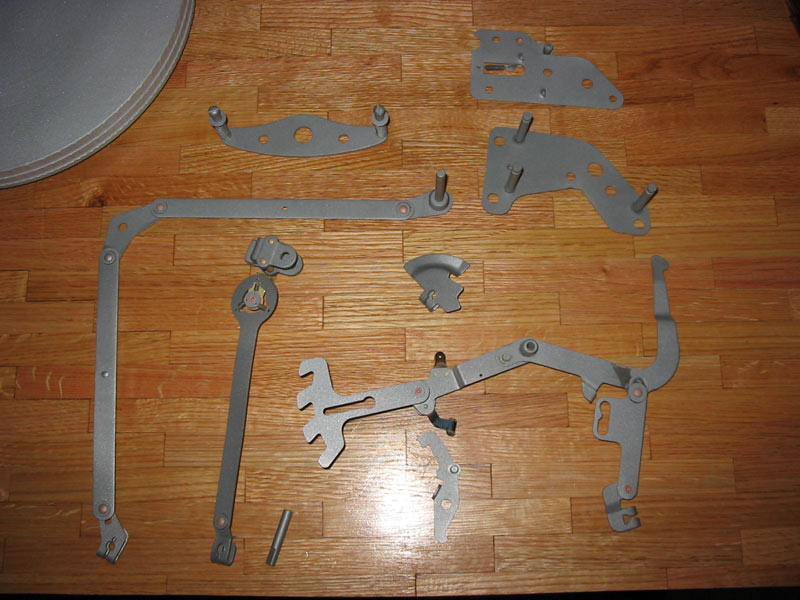

Glasperlen war auch eine gute Option für das Schaltgestänge. Manuelle Reinigung erzeugt eben keine so gute Oberfläche.

Außerdem ist die Beschichtung cadmiumhaltig, das wegstrahlen zu lassen ist also sicher eine gute Idee. Es ist der gelbliche Überzug sämtlicher Schalthebel. So werden natürlich auch sämtliche verharzte Fettreste und der Schmutz der Jahrzehnte weg geblasen.

Die fertigen Teile, sorgfältig die Restpartikel entfernen. Am besten mit einem Pinsel.

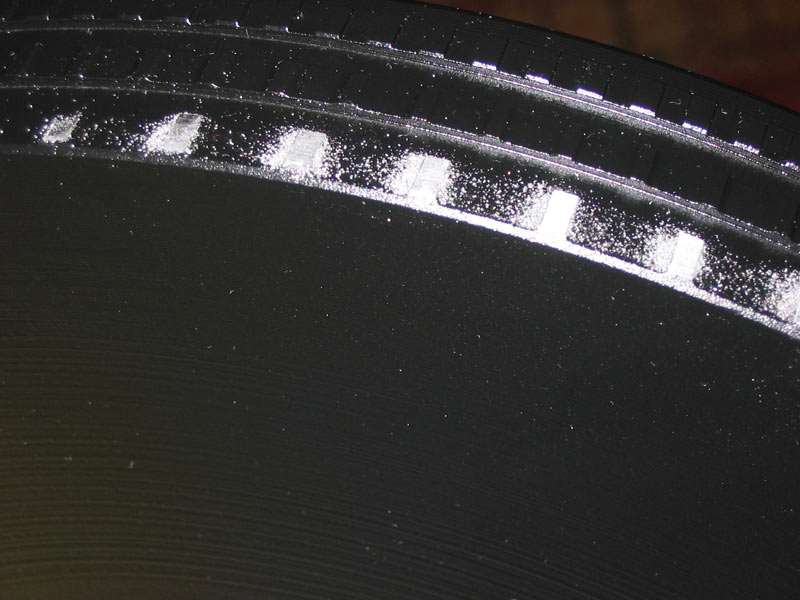

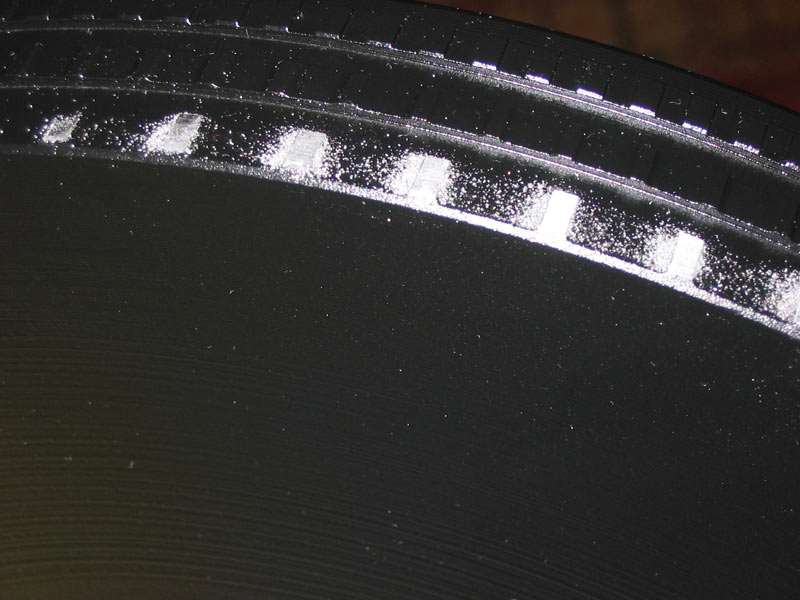

Nach der Lackierung des Plattenteller habe ich die Stroboskopmarken wieder frei gefeilt. Dauert etwa 90 Minuten.

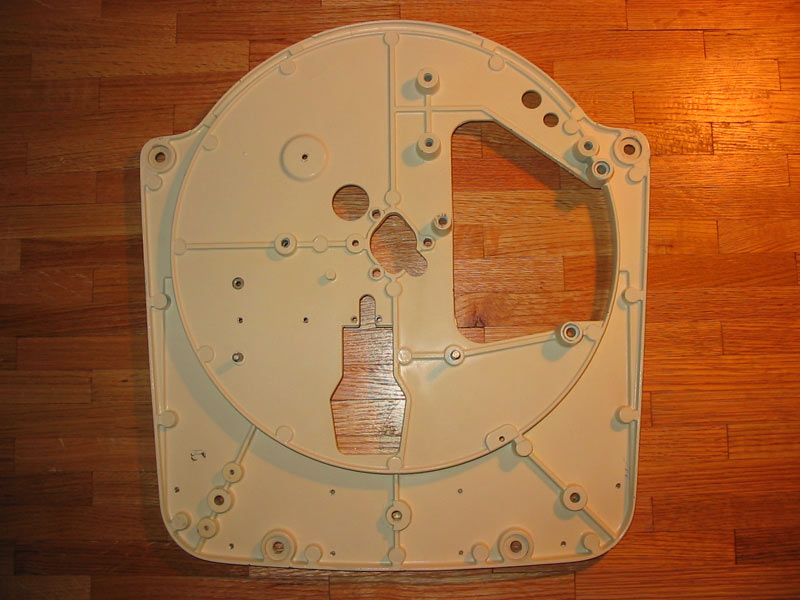

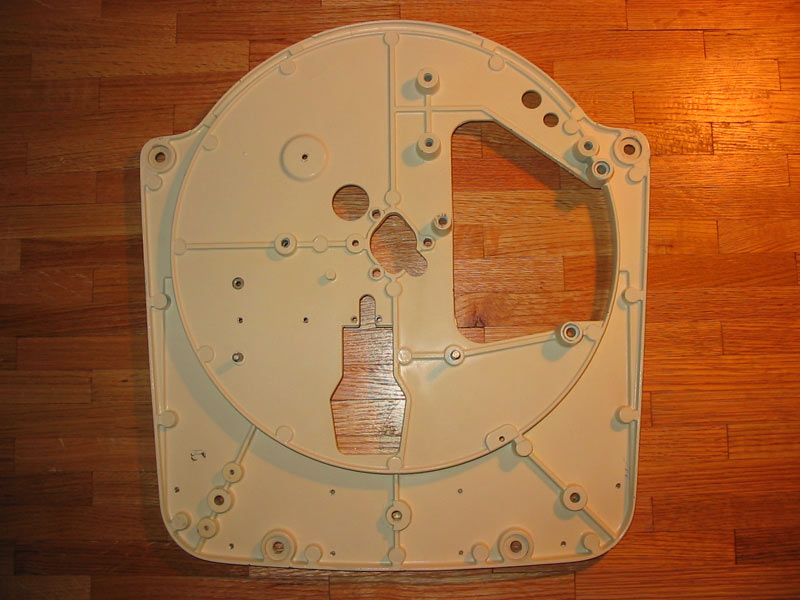

Was ist mit der Grundplatte?

Zunächst habe ich mich entschieden den Original Emaillack zu erhalten. Nach intensiven Reinigungs- und Polierarbeiten blieben immer noch kleine Abnutzungen und die Farbe erschien vergilbt. Nicht jede Patina ist cool.

Daher habe ich mit einem passenden Ton Autolack die Grundplatte überlackiert. Hier das ‚Vorher‘.

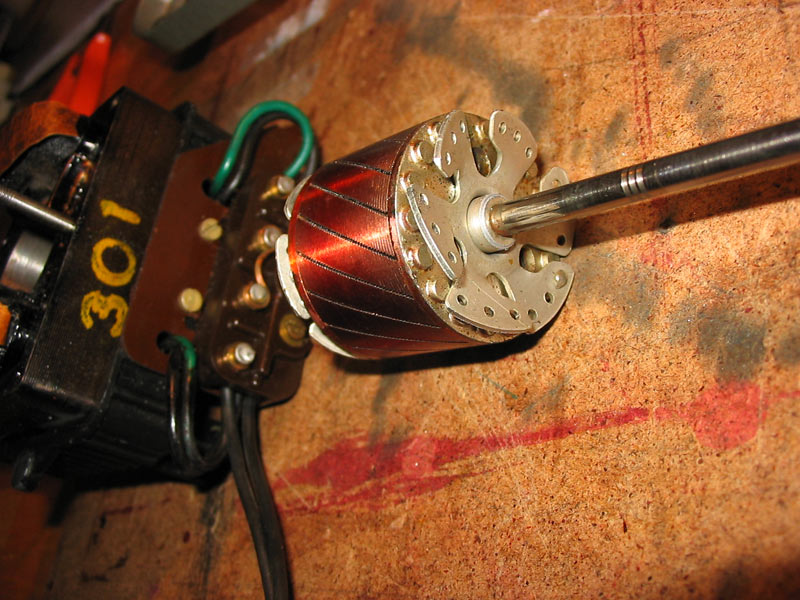

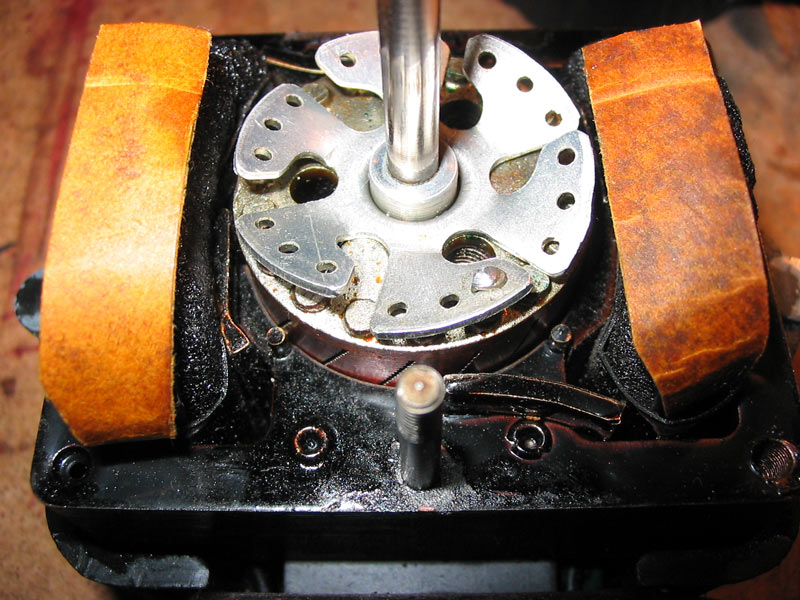

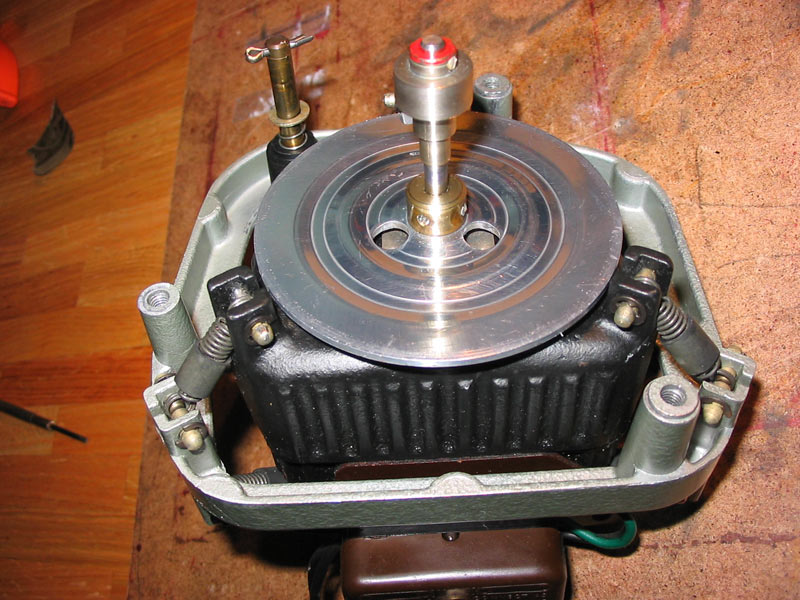

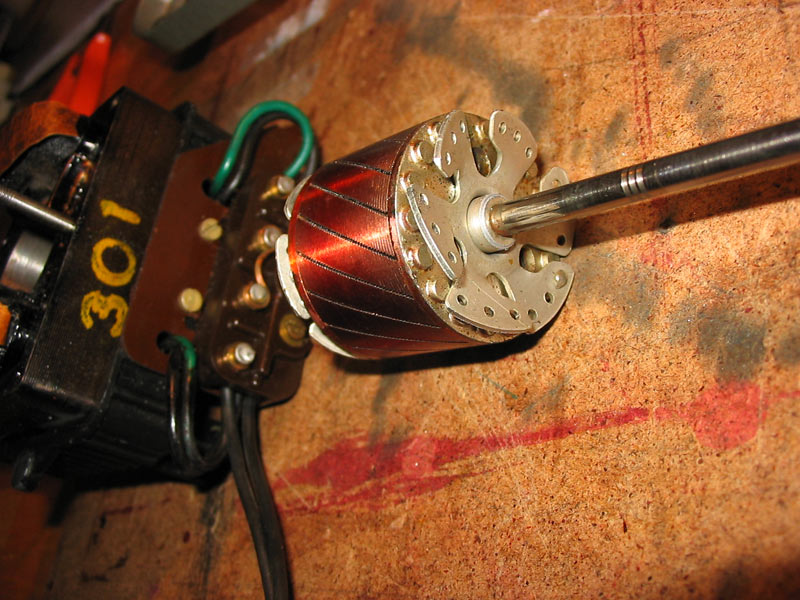

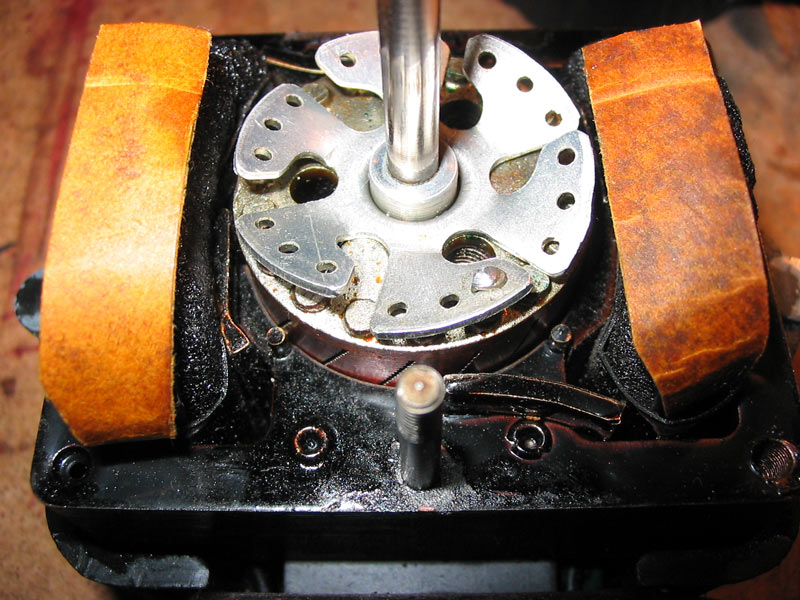

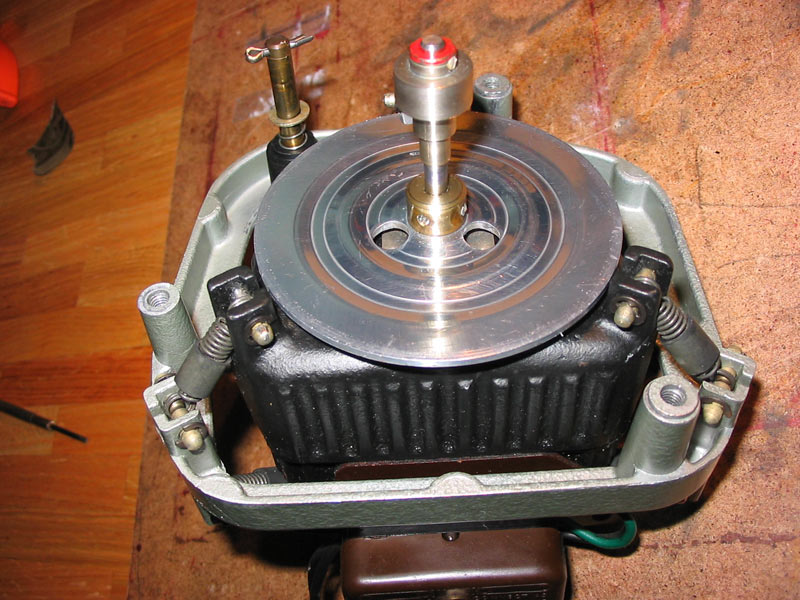

Der Motor wurde komplett demontiert und gereinigt.

Speziell das untere Lager hat sehr viel Schmutz angesammelt und das Fett oder Öl war verharzt. Die Kugel im unteren Lager war komplett fest im Harz. Zum erneuten Fetten der Lager habe ich Shimano Fahrradfett benutzt. Es hat eine hohe Qualität und ich hatte es…

Ich habe den fertigen Player auf einem MDF Brett aufgebaut. Es soll nicht die endgültige Zarge sein, es ist ein reines Aufbauwerkzeug. Die Beine sind hoch genung, das man in der Einbausituation alle Hebel erreichen und einstellen kann, sehr hilfreich.

Die Feineinstellung des wieder zusammengefügten Spielers erforderte einiges an Geduld, bis alle Hebel wieder ihre ursprüngliche Funktion hatten. Speziell die Einstellung der Wirbelstrombremse ist knifflig.

Nach einigen Umwegen über diverse Holz- und Steinzargen habe ich nun eine gefunden, die in allen klanglichen Aspekten überzeugt.

Restaurierung eines Garrard 301

Ich habe meinen Garrard 301 auf Ebay in ziemlich schlechtem Zustand gekauft. Allerdings war das Risiko angesichts des geringen Preises vertretbar.

Falls Sie den Garrard 301 noch nicht kennen, eine Googlesuche oder aber das Garrard Forum auf ‚Vinylengines‘ (Englisch) bringen weitere Informationen.

Eine kurze Zusmmenfassung des Zustands:

- Der Einschalt- und Geschwindigkeitshebel waren abgebrochen,

- Der Teller war oxidiert,

- Das Hauptlager lief ruhig

- Der Motor war verharzt

- Das Reibrad war in gutem Zustand.

Ich habe den Spieler komplett demontiert, um alle Metallteile glasperlen zu lassen (wesentlich feiner als Sandstrahlen). So konnte die Oxidschicht sauber entfernt werden. Nicht vergessen die Tellerachse und die Innenseite mit Pappe und Klebeband zu schützen.

Der ‚leidende‘ Teller im Detail.

Glasperlen war auch eine gute Option für das Schaltgestänge. Manuelle Reinigung erzeugt eben keine so gute Oberfläche.

Außerdem ist die Beschichtung cadmiumhaltig, das wegstrahlen zu lassen ist also sicher eine gute Idee. Es ist der gelbliche Überzug sämtlicher Schalthebel. So werden natürlich auch sämtliche verharzte Fettreste und der Schmutz der Jahrzehnte weg geblasen.

Die fertigen Teile, sorgfältig die Restpartikel entfernen. Am besten mit einem Pinsel.

Nach der Lackierung des Plattenteller habe ich die Stroboskopmarken wieder frei gefeilt. Dauert etwa 90 Minuten.

Was ist mit der Grundplatte?

Zunächst habe ich mich entschieden den Original Emaillack zu erhalten. Nach intensiven Reinigungs- und Polierarbeiten blieben immer noch kleine Abnutzungen und die Farbe erschien vergilbt. Nicht jede Patina ist cool.

Daher habe ich mit einem passenden Ton Autolack die Grundplatte überlackiert. Hier das ‚Vorher‘.

Der Motor wurde komplett demontiert und gereinigt.

Speziell das untere Lager hat sehr viel Schmutz angesammelt und das Fett oder Öl war verharzt. Die Kugel im unteren Lager war komplett fest im Harz. Zum erneuten Fetten der Lager habe ich Shimano Fahrradfett benutzt. Es hat eine hohe Qualität und ich hatte es…

Ich habe den fertigen Player auf einem MDF Brett aufgebaut. Es soll nicht die endgültige Zarge sein, es ist ein reines Aufbauwerkzeug. Die Beine sind hoch genung, das man in der Einbausituation alle Hebel erreichen und einstellen kann, sehr hilfreich.

Die Feineinstellung des wieder zusammengefügten Spielers erforderte einiges an Geduld, bis alle Hebel wieder ihre ursprüngliche Funktion hatten. Speziell die Einstellung der Wirbelstrombremse ist knifflig.

Nach einigen Umwegen über diverse Holz- und Steinzargen habe ich nun eine gefunden, die in allen klanglichen Aspekten überzeugt.